The Citizen A20 is a versatile 6-axis turn-mill machine engineered for high-precision machining of complex parts across industries such as medical, aerospace, automotive, and electronics. By integrating both turning and milling processes in a single setup, the A20 significantly reduces cycle times and boosts productivity. It features dual spindles, allowing for continuous machining on both ends of a workpiece, eliminating the need for secondary operations. The machine’s modular tooling system offers quick tool changes, enhancing its flexibility for various production needs.

The A20’s compact design makes it suitable for space-constrained shops, while its advanced CNC control ensures high precision and repeatability. Ideal for high-mix, low-volume production environments, the machine can efficiently handle intricate operations. Optional features like an automatic bar feeder and high-pressure coolant system further increase its productivity and operational efficiency. Overall, the Citizen A20 provides an excellent balance of precision, versatility, and efficiency, making it a valuable asset for manufacturers requiring complex part production in a compact footprint.

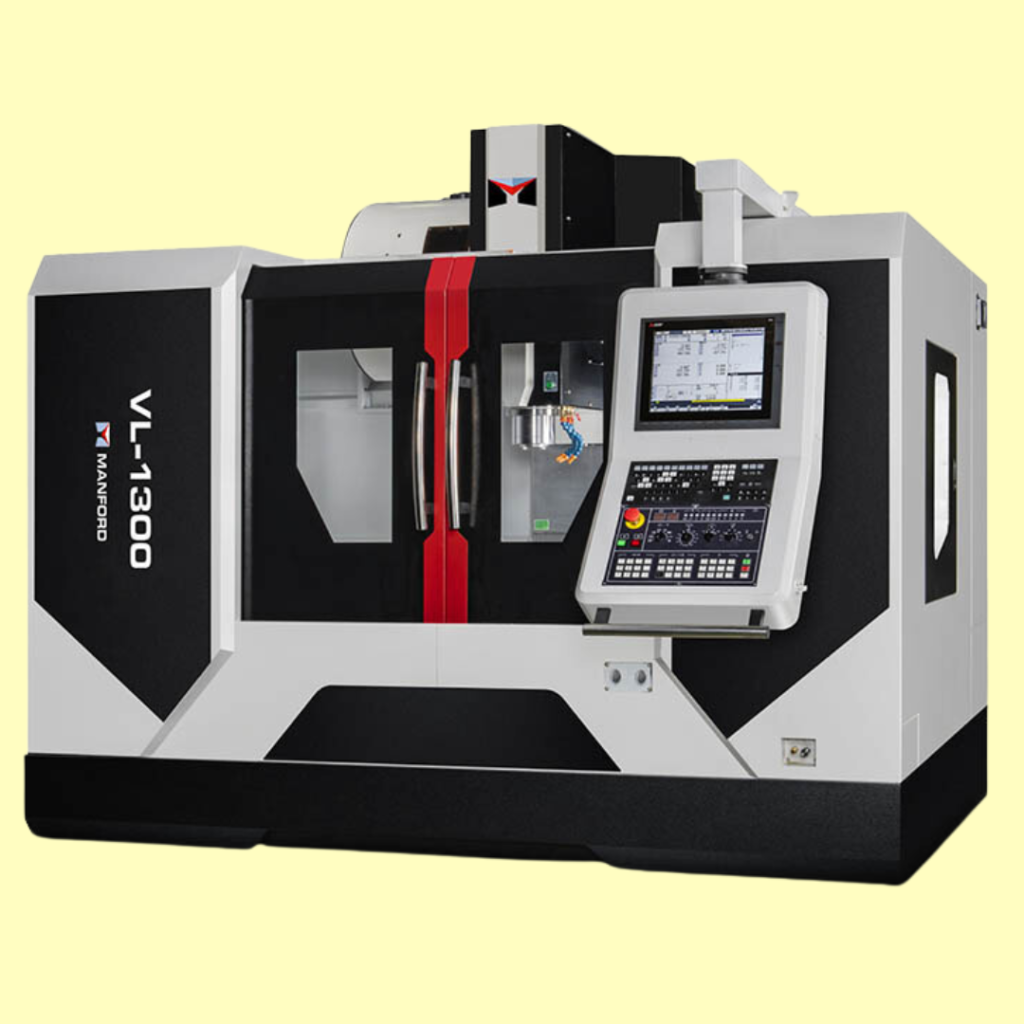

The VL 1300 employs high precision fine ground ball screws for optimum motion control accuracy.

The sufficient depth from spindle center to machine not only accommodates 700 mm. Y-axis travel but also enables easy access for large diameter facing milling cutter.

Y-axis with 4 roller linear guide ways.

Six Roller shoes are employed on the machine column that firmly supports the headstock to perform heavy duty cutting.

This type of spindle is ideal for heavy cutting application that results in higher material removal rate. In addition, the spindle also features high precision and low thermal growth.

The double chip augers deliver chips out of machine during cutting, that prevent chips from depositing in the machine. Another benefits is to save time in chip.

3-Axis CNC (Vertical Machining Center)

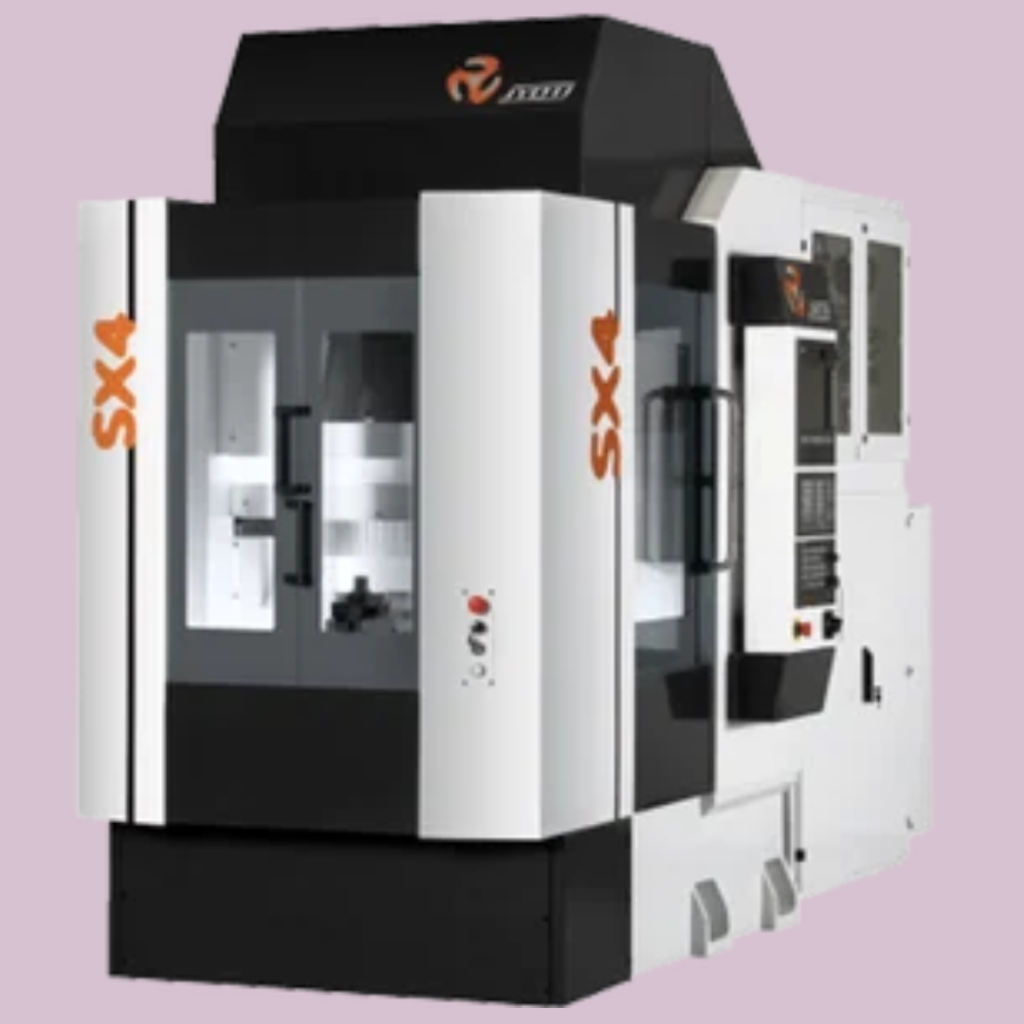

SX4 machines are totally dedicated for fast Milling, Drilling and Tapping operations for small size of components. The SX4 machines are with compact foot print equipped with integral work piece changer, a fast auto tool changer and high speed electro spindle. The concept of base and column structure with all the moving axis mass on the column helps very high dynamics while maintaining the machining accuracy.

Key Features

- Column moving fast drill tap center.

- Integral work piece changer for reduce non cutting time.

- High speed 12000 rpm HSK 50A electro spindle.

- High rate of spindle acceleration and decelerations.

- High speed servo driven disc type tool changer.

- Electrical with quality device & panel AC.

- Auto & manual coolant.

- Efficient chip disposal.

- Centralized & programmable lubrication.

The QUICK TURN NEXUS 200-II MY CNC turning center with Multi-Tasking capability brings together advanced technology, productivity and value to deliver exceptional performance for shops of all sizes. As an (MY) configuration, the machine features milling capability and Y-axis functionality along with a standard through-hole chuck package, and integral turning spindle motor to process a wide range of parts in a single setup.

Chuck Size Main Spindle: 8″

Maximum Machining Diameter: 380mm

Maximum Bar Work Capacity: 65mm

Maximum Machining Length: 541mm