4th Axis CNC Machining

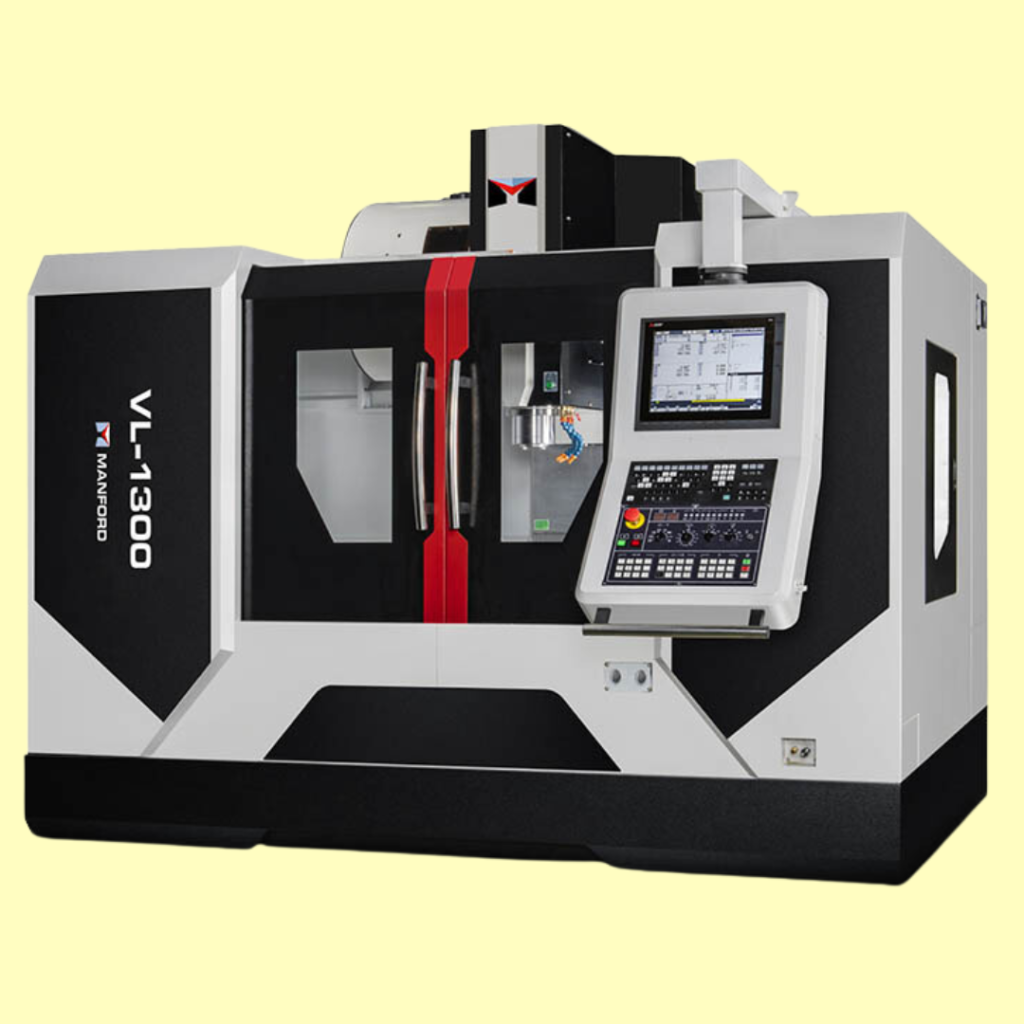

The Manford VL 1300 is a 4-axis Vertical Machining Center (VMC) that is designed for high-precision and efficient machining operations. Here are some of its key features and specifications:

Specifications:

- Table Size: Typically, the table size is around 1500 mm x 670 mm, offering ample space for various workpieces.

- X-Axis Travel: 1300 mm

- Y-Axis Travel: 670 mm

- Z-Axis Travel: 660 mm

- Spindle Speed: The spindle speed generally ranges up to 8000 RPM, depending on the specific configuration.

- Spindle Motor Power: The spindle motor is often powered by a high-torque motor, usually around 15 kW.

- Tool Magazine Capacity: Usually equipped with a 24-tool magazine, allowing for quick tool changes and efficient machining.

- CNC Control System: Typically equipped with a FANUC or Siemens CNC control system, providing advanced features for precision machining.

Features:

- High Rigidity Structure: The machine is built with a rigid structure, providing stability during heavy cutting operations.

- 4-Axis Capability: In addition to the standard X, Y, and Z axes, the machine has a rotary axis, allowing for complex machining tasks.

- Precision Machining: Designed for high-precision machining with tight tolerances.

- Automatic Tool Changer: The machine is equipped with an automatic tool changer (ATC) for efficient and quick tool changes.

Applications:

- Ideal for automotive, aerospace, and general engineering industries.

- Suitable for machining complex components requiring high precision and multiple operations.

Specification

| X travel | 1,300 mm |

|---|---|

| Y travel | 700 mm |

| Z travel | 700 mm |

| Spindle nose to table surface | BT40:130 ~ 830 mm / BT50:130 ~ 830 mm |

Table size | 1,450 x 700 mm |

T-slot (Q’ty x Size x Dist) | 5 x 18 x 125 mm |

| Max. Table Load | 1,500 kgs |

| CNC Control | Mitsubishi / Fanuc / Siemens / Heidenhain / Fagor |

Spindle | |

|---|---|

Spindle Transmission | Belt type |

Spindle Taper | BT40 / BT50 |

| Spindle Speed | BT40:8,000 rpm / BT50:6,000 rpm |

| Spindle motor | 7.5 / 11 kW (*) |

Other items | |

|---|---|

ATC Capacity | ATC Genoa type 20 tools / Arm type 24 tools |

The VL 1300 employs high precision fine ground ball screws for optimum motion control accuracy.

The sufficient depth from spindle center to machine not only accommodates 700 mm. Y-axis travel but also enables easy access for large diameter facing milling cutter.

Y-axis with 4 roller linear guide ways.

Six Roller shoes are employed on the machine column that firmly supports the headstock to perform heavy duty cutting.

This type of spindle is ideal for heavy cutting application that results in higher material removal rate. In addition, the spindle also features high precision and low thermal growth.

The double chip augers deliver chips out of machine during cutting, that prevent chips from depositing in the machine. Another benefits is to save time in chip.